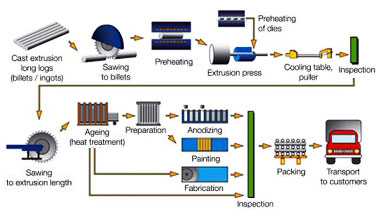

C360 brass is a wrought alloy, this means it is manufactured via an extrusion process. This process involves the casting of a large billet, reheating this billet, and extruding a smaller diameter metal through a die in an extrusion press.

C360 free machining brass is one of the most commonly used brass alloys today. As the name “free machining” implies, this alloy is engineered to maximize the machining capability of today’s hi speed machining equipment. C360 brass is used in a wide variety of applications from plumbing components, valve stems, fittings, and various adapters. The ease of machinability makes C360 free machining brass an excellent choice for higher volume production work.

C360 brass is a wrought alloy, this means it is manufactured via an extrusion process. This process involves the casting of a large billet, reheating this billet, and extruding a smaller diameter metal through a die in an extrusion press. In order for this process to work you must start with a much larger billet to produce a smaller extruded diameter. For this reason there are certain limitations on the size of the extruded diameter. Generally the largest extruded diameter that can be extruded is approximately 4” to 4.5”. For a large number of the C360 brass end uses this large enough to suffice. Unfortunately for certain uses, 4.5” isn’t large enough.

For situations where the max extruded diameter of C36000 brass isn’t large enough for the finished component, there are a couple of options to consider.

Option #1:

The easiest option would be to switch to a different cast alloy with similar properties. Often, we see customers in this situation successfully substitute C93200 bearing bronze for the large diameter C36000 brass. The C93200 bronze is quite easy to machine (machinability rating of 80 compared to 100 for C360 brass). The C93200 also has natural bearing properties due to the lead content much like the C360 brass. The advantage of using C93200 bearing bronze for the larger diameter is that it is a cast alloy. This process allows larger diameters not possible with an extruded product like C360 brass.

Option #2:

A second option for large diameter C36000 brass bar stock is what we called cast and turned C360. This is achieved by casting C360 brass and eliminating the extrusion process. After the C360 is cast, the diameter is machined, or turned, to a specified size. This method will give you a bar stock with the same chemical composition as extruded C360 brass but with slightly different mechanical properties. Depending on the application this may be an acceptable solution.

Here at National Bronze Mfg. Co. we can provide either of the above options. For more information on large diameter C36000 brass bar stock, follow the links below or contact one of our experience Sales Technicians today.